HPLC Mobile Phase Filtration:

The Key Step to Enhance Chromatographic Efficiency

Table of Contents

What is HPLC?

Why Does HPLC Mobile Phase Need Filtration?

Why Does Filtration Improve HPLC Stability?

How to Perform HPLC Mobile Phase Filtration?

ROCKER Complete Solvent Purification Solution

How to Choose a Membrane Filter?

What is HPLC?

High Performance Liquid Chromatography (HPLC) is an efficient technique for separation and analysis,

capable of separating mixtures and quantitatively analyzing the proportion of each component. HPLC is widely used in various scientific fields,

including pharmaceuticals, food, cosmetics, health supplements, narcotics, forensic science, and environmental matrices.

Why Does HPLC Mobile Phase Need Filtration?

In HPLC, the quality of the mobile phase directly affects the accuracy, reproducibility,

and lifespan of the instrument. Common mobile phases such as acetonitrile (ACN), methanol (MeOH),

or formic acid may contain impurities such as bubbles, particles, contaminants,

or microorganisms. These impurities can cause several negative effects on the HPLC system,

including column clogging, excessive noise and background signals, and reduced equipment lifespan.

What are the consequences of not filtering the mobile phase?

- Column clogging: Particle buildup affects the stability of flow rate, leads to retention time shifts,

and may shorten the column lifespan. - Pump damage: Particles may wear out the piston and seals, causing baseline drift and flow fluctuations.

- System clogging: May result in increased backpressure, leading to system shutdowns.

- Interference with analysis: Interaction with column materials can cause noise

and background elevation in chromatograms, and even ghost peaks

(known as pseudo peak, eigen peak, induced peaks). - Microbial contamination: Aqueous buffers may promote microbial growth, producing contaminants that affect results and clog the system.

In addition, many HPLC methods involve solvent mixing and/or the addition of salts,

such as phosphates or acetates. These extra mixing steps or additives may result in particles if not fully dissolved.

Therefore, filtration before use is recommended to ensure solution purity.

To protect the HPLC system, extend the column’s lifespan,

and achieve consistent, accurate, and reproducible results,

mobile phase filtration is an essential and critical step.

Why Does Filtration Improve HPLC Stability?

Vacuum filtration is a commonly used method for filtering mobile phases.

It effectively removes particles and contaminants, preventing system blockages, reducing contamination and wear,

and extending the lifespan of consumables. Removing contaminants also lowers signal noise, resulting in clearer and more reliable analytical results.

Additionally, vacuum filtration serves to degas the solvent, removing dissolved oxygen,

which helps minimize oxidative degradation of samples and solvents,

thereby improving system stability and detector sensitivity.

In short, filtering the mobile phase is the simplest and most economical way to maintain HPLC performance and achieve high-quality analysis.

How to Perform HPLC Mobile Phase Filtration?

Traditionally, HPLC solvent filtration uses a glass funnel and Erlenmeyer flask, but this approach comes with the following risks:

- After filtration, the solvent must be transferred to a storage bottle or serum bottle, which introduces the risk of leakage and cross-contamination.

- The solvent must be manually lifted and poured into the funnel, which can easily result in spillage due to unstable hand movement or pouring angle.

For volatile or toxic solvents,

vapors may directly contact the operator’s eyes, mouth, or nose, posing health risks with long-term exposure.

ROCKER Complete Solvent Purification Solution

Newly launched continuous filtration device – designed to meet your large-volume solvent filtration needs

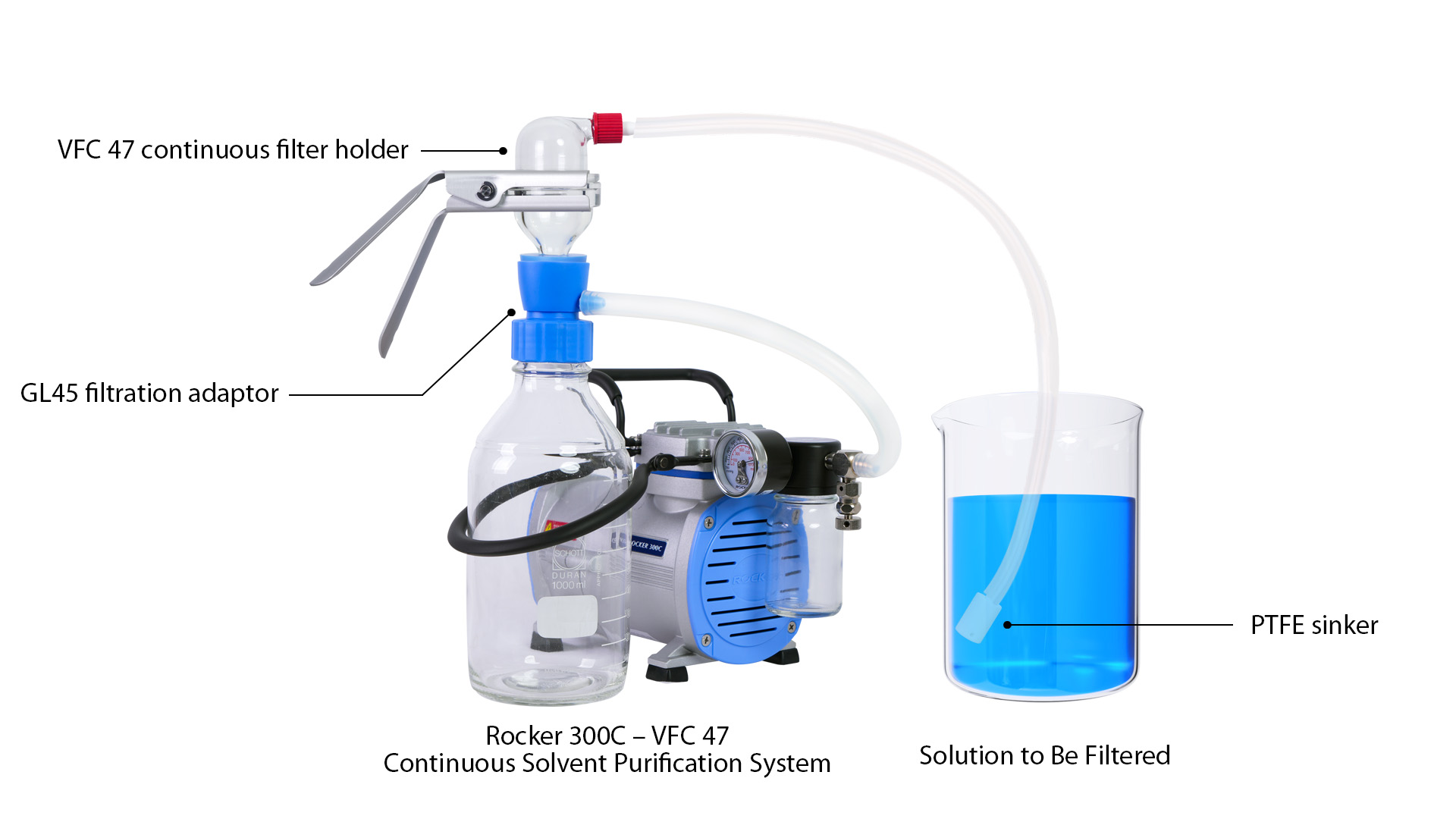

Rocker 300C – VFC 47

- Continuous feeding with direct storage in serum bottles, eliminating the need for manual transfer and avoiding cross-contamination

- Comes standard with a sinker, allowing for efficient liquid suction and reduced residue

- Equipped with GL45 filtration adapter, allowing direct collection of filtrate into GL45 serum bottles, avoiding repackaging and secondary contamination

| Model | Other Traditional Bottle Sets | Rocker 300C – VF 12 |

Rocker 300C – VFC 47 (NEW) |

| Product Image |  |

|

|

| Contact Material | Borosilicate Glass | Borosilicate Glass | Borosilicate Glass |

| Vacuum Pump | Optional | PTFE Coated Vacuum Pump | PTFE Coated Vacuum Pump |

| Direct Filtration into Serum Bottle | X | V | V |

| Filtration Method | Manual Feeding | Manual Feeding | Continuous Filtration |

| Sinker Included | X | X | V (PTFE sinker, leaves no residue) |

| Safety & Space Saving | X |

V (Saves 50% space) |

V (Saves 50% space) |

The following is the system diagram of the VFC Continuous Solvent Filtration System. For details, please refer to the installation video or see the steps below:

- Assemble the Equipment:

Attach the GL45 adaptor and VFC 47 continuous glass filter holder in sequence to the GL45 bottle.

Connect the silicone tubes according to the diagram.

* If using an Erlenmeyer flask, insert the No. 8 silicone stopper directly into the bottle mouth or replace it with a suitable size. - Place the Membrane:

Place the membrane on top of the VFC 47 filter support, put back the glass cover, and clamp tightly with the aluminum clamp. - Start Filtration:

Place the sinker (with silicone tubing attached) into the unfiltered solution. Turn on the vacuum pump to begin filtration. - Storage:

After filtration, remove the tubing, filter holder, and adaptor. Turn off the pump.

Seal the bottle with the original GL45 cap to store the solvent directly.

How to Choose a Membrane Filter?

Selecting the appropriate membrane is key to ensuring effective filtration. Choices should be based on the specific HPLC system and application:

| Pore Size | Purpose | Common Materials | |

| 0.45 μm | General HPLC mobile phase filtration | PTFE, Nylon | |

| 0.2 μm | Ultra High Performance Liquid Chromatography (UPLC / UHPLC) or sterilization | PVDF, PTFE | |

Membrane material should also be selected based on the chemical properties of the solvent. Common materials include PTFE, PVDF, Nylon and so on.

Below are membrane types referenced in methods published or recommended by the Taiwan Food and Drug Administration (TFDA):

| Title | Author (s) | Membrane filter | |

| Pore Size | |||

| DETERMINATION OF PRESERVATIVES IN FOODSTUFFS | P. Willetts et.al., 1996 | 0.45 μm | |

| HPLC Method for Determination of inositol Tri-, Tetra-, Penta-, and Hexaphosphates in Foods and Intestinal Contents | A.-S. SANDBERG, R. AHDERINNE, 1986 |

0.45 μm | |

| Optimization of a new mobile phase to know the complex and real polyphenolic composition: towards a total phenolic index using high-performance liquid chromatography | Tsao, R., & Yang, R., 2003 | 0.2 μm / 0.45 μm | |

Applications

- HPLC mobile phase filtration

- Solvent purification and degassing

- Removal of microorganisms and contaminants

References

- Mobile phase filtration

- The Importance of Filtration in Optimizing (U)HPLC and LC-MS Performance

- Top Tips for LC-MS Sample Preparation